Add to Cart

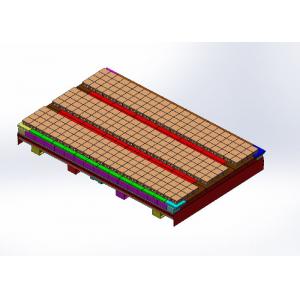

Clay Brick Tunnel Kiln Cart Refractory Brick Material

Lightweight Refractory Brick Material Anti Alkali Clay Heat Insulation Bricks

General Description of Lightweight Refractory Brick Material Anti Alkali Clay Heat Insulation Bricks:

1. Clay refractory bricks/ Lightweight Refractory Bricks are made of 50% soft clay and 50% hard clay clinker according to a certain particle size through slurry treatment, molding, drying and baking.

2. The size of ordinary refractory bricks/Lightweight Refractory Bricks is 230*114*65(mm), we can also produce bricks according to the customer's drawings.

3. Clay fired bricks/Lightweight Refractory Bricks are weak acid refractory products, which can resist acid slag and acid gas erosion. Clay bricks have good thermal shock performance and are resistant to rapid cooling and rapid heating.

4. Clay fired bricks/Lightweight Refractory Bricks are widely used in large and medium-sized hot blast stoves, electric furnace insulation layers, blast furnace gas risers and linings for cooling fireplaces.

Technical Parameters of Clay refractory bricks/ Lightweight Refractory Brick Material Anti Alkali Clay Heat Insulation Bricks:

| Item | ZN-45 | ZN-40 | ZN-36 |

| Al2O3 (%) ≥ | 45 | 40 | 36 |

| refractoriness under load(℃) | 1430 | 1380 | 1350 |

| permanent linear change on heating(1400℃*2h)% | -0.2~+0.1 | -0.3~+0.1 | -0.4~+0.1 |

| volume density(g/cm3) | 2.00-2.40 | ||

| apparent porosity ≤ | 16 | 19(22) | 22(24) |

| cold crushing strength(Mpa)≥ | 60 | 40(35) | 35(30) |

Application of Refractory Bricks in Clay Brick Plant Red Clay Brick Production Line Fired Bricks:Safety zone, Pre-heating /Calcining zone in rotary kiln.